Flexible manufacturing

A flexible manufacturing system (FMS) is a method for producing goods that is readily adaptable to changes in the product being manufactured, both in type and quantity. Machines and computerized systems are configured to manufacture different parts and handle varying levels of production. A flexible manufacturing system (FMS) gives manufacturing firms an advantage to quickly change a manufacturing environment to improve process efficiency and thus lower production cost. However, upfront costs may be greater for installing specialized equipment that allows for flexibility and customization.

Bridge manufactures all its components In- house this makes us adaptable and ensures our inventory reflects customer needs. Our production and assembly facilities are located in Taiwan. Production lines are equipped with high standard SMD machines, auto-insertion machines, burn-in chambers and state of the art testing rooms. More than 25,000 square-meters of manufacturing space allows for flexible expansion of production expansion when needed.

Quality Guarantee

All Bridge products undergo quality checks before being shipped out to customers to avoid quality discrepancies. As a result, our global customers highly appreciate our price-performance ratio and quick delivery services. We approach each inquiry with the customer’s bottom line in mind. We offer a wide range of products that enable us to provide our customers with unique solutions that meet their requirements, while being cost-effective and having short lead times.

We understand that when we define a strategic mutual vision of success for all the parties involved and the partners agree on what success looks like for both sides and how each can leverage the strengths of the other then the foundation is established. When expectations are aligned great partnerships are built, here are the 4 core principles Bridge Components uses to establish lasting partnership:

Common Bond

Constant Support

1

Value

Security Professionals

2

Communication

Equipments

3

25

Year Experience

4

System Capabilities

Combining engineering and manufacturing to produce RF solutions for leading global brands. Our production and assembly facilities are located in Taiwan. Production lines are equipped with high standard SMD machines, auto-insertion machines, burn-in chambers and state of the art testing rooms.

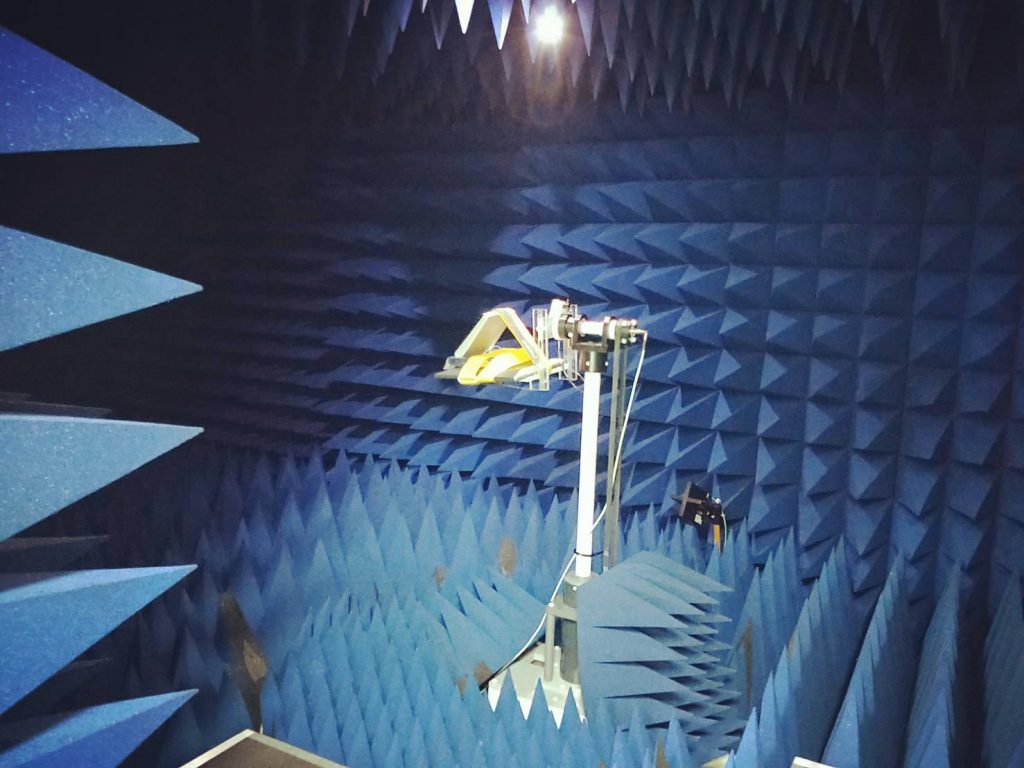

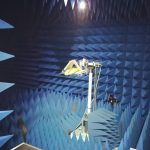

Microwave Anechoic Chamber

State-of-the-art Microwave Anechoic Chamber, offers high performance pyramidal and convoluted foam absorber materials designed for use in antenna range tests.

Testing Equipment

A wide rage of testing equipment. Including but not limited to High Voltage Insulation Tester, Desktop X-Ray RoHS Analyzer, PNA-Network-Analyzer, VNA Network Analyzer, Signal Generator, Spectrum-Analyzer, Laser Welding Machine, UV-Resistance Chamber, Bending Tester, Salt-spray Tester, Cable Tester, CNC Bending Machine, Two Zone Thermal Shock Test-Chambers, Aginger Chamber, Color Controller Light Box,X-Ray Coating Thickness Gauge, Automatic Coaxial Stripper, Constance Temperature & Humidity Chamber, Passive Inter modulation Tester, 2.5D-Projector, 3D Projector & Auto Tap Screw

Who are we

Learn about the Bridge company mission , vision and values

What we do

Solutions designed to integrate multiple facets of a company’s business

Customers

Bridge serves a wide range of customer types from all industries.

Quality

Bridge maintains world class manufacturing, lear now we do this

Locations

We have mutiple sales and maufacturing sites across Asia

Sign up for the latest insights, delivered right to your inbox

About Bridge

Manufacturer and supplier of high power and passive qualified RF and microwave equipment for signal enhancement infrastructure with factories in Taiwan producing high-quality products.

Applications

Quick Links

Contact Info

Phone: +886-4-23832365

sales@bridgecomponets.com